Project

Country / Region: Nevada, USAIndustry: MiningApplication: Gold MiningClient Name: Silver Standard Gold Co., Marigold Mine

Client Description

In production since 1988, Marigold produces an average of approximately 220,000 ounces of gold per year. The mine has faced, through the years, a strong increase in production as well as drilling size. Pressure for reducing costs has affected the operation, constantly seeking to reduce total drilling costs. Drillco has been a partner and supplier since the late 90’s.

Case Study

Back in 2004, they had 4 running drills with P8.1 hammer and 8 ¾ bits, which where operated under the following procedure to maximize useful life: reverse the new hammer, rebuilt the flip hammer, reverse the rebuilt hammer and finally taking the hammer out of services after the las flip was done. After 6 months of analyzing the wear down of each hammer, we came to the conclusion that the hammer could be rebuilt a second time, but it would need a second piston due to its short life. Out team proposed a new procedure to the customer, which meant improving the metallurgic design on the piston to improve its average life, and modifying the maintenance procedure.

Results

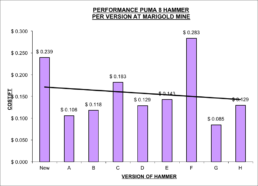

The average life of the piston was improved by 87,5%, from 64,000 feet to over 120,000 feet The cost per foot drilled was improved by 3%, from $0.20 – $0.24 per foot to $0.13 to $0.15 per feet

Results Chart

Let's Talk

Today, you can find Puma by Drillco® products operating from the Arctic Circle to Patagonia and from Scandinavia to the Sahara Desert.

Contact Us ⟶